Detailed content

Introduction

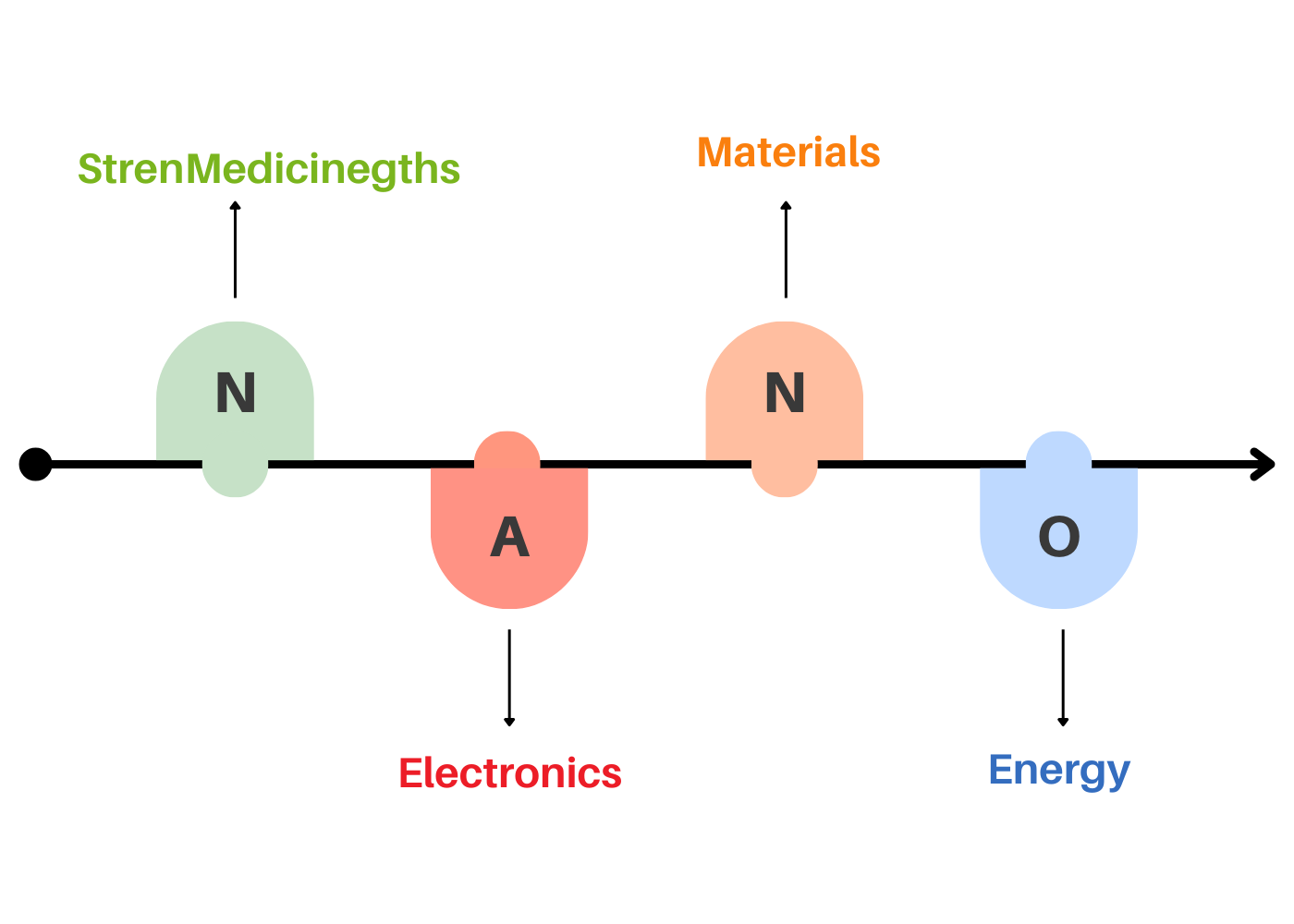

Nanotechnology, the manipulation of matter at the nanoscale, holds immense promise for revolutionizing various fields, from medicine and electronics to materials science and energy. At the heart of nanotechnology lie diverse approaches aimed at fabricating, characterizing, and utilizing materials and devices at the nanoscale. In this comprehensive exploration, we delve into the various approaches to nanotechnology, encompassing bottom-up and top-down methods, self-assembly techniques, and hybrid approaches. Each approach brings unique advantages and challenges, shaping the landscape of nanotechnology research and applications.

1.Bottom-Up Approaches

Bottom-up approaches involve building nanostructures from atomic or molecular constituents, enabling precise control over structure and properties. Key techniques include molecular self-assembly, chemical vapor deposition (CVD), and molecular beam epitaxy (MBE).

1.1 Molecular Self-Assembly

Molecular self-assembly harnesses the inherent properties of molecules to spontaneously organize into ordered structures. Examples include DNA nanotechnology, where DNA molecules serve as programmable building blocks, and peptide self-assembly, exploiting the folding properties of peptides to create nanostructures. Self-assembly offers high precision and scalability but requires careful design and control of molecular interactions.

1.2 Chemical Vapor Deposition (CVD)

CVD involves depositing thin films of materials onto substrates by exposing precursor gases to a heated substrate surface, where chemical reactions occur to form the desired material. CVD enables precise control over film thickness and composition and is widely used in semiconductor manufacturing and thin-film coatings. However, achieving uniformity and purity at the nanoscale poses challenges.

1.3 Molecular Beam Epitaxy (MBE)

MBE relies on the precise deposition of atoms or molecules onto a substrate under ultra-high vacuum conditions. By controlling the flux of incoming species, MBE allows for the growth of atomically thin layers with exceptional control over crystal structure and composition. MBE is crucial for fabricating semiconductor heterostructures and quantum dots but requires sophisticated equipment and expertise.

2.Top-Down Approaches

Top-down approaches involve carving nanostructures out of bulk materials, often using lithography or etching techniques. While less precise than bottom-up methods, top-down approaches offer scalability and compatibility with existing manufacturing processes.

2.1 Lithography

Lithography is a cornerstone technique in nanofabrication, capable of defining nanoscale patterns on surfaces with high precision. Techniques such as photolithography, electron beam lithography (EBL), and nanoimprint lithography (NIL) enable the creation of features down to a few nanometers. Lithography underpins the semiconductor industry, enabling the production of integrated circuits and microelectromechanical systems (MEMS).

2.2 Etching

Etching techniques selectively remove material from a substrate to sculpt nanostructures. Wet etching uses liquid chemical solutions to dissolve unwanted material, while dry etching methods such as reactive ion etching (RIE) and plasma etching rely on reactive gases to achieve high selectivity and anisotropy. Etching is crucial for defining device geometries in semiconductor fabrication and creating nanostructured surfaces for applications in optics and catalysis.

3.Hybrid Approaches

Hybrid approaches combine elements of bottom-up and top-down techniques to achieve complex nanostructures with enhanced functionality.

3.1 Template-Assisted Synthesis

Template-assisted synthesis combines the precision of bottom-up assembly with the scalability of top-down processing. Templates such as nanoporous membranes or lithographically patterned substrates guide the growth of nanostructures, enabling precise control over size, shape, and orientation. Template-assisted synthesis is used in the fabrication of nanowires, nanotubes, and nanoparticle arrays for applications in electronics, sensing, and energy conversion.

3.2 Directed Self-Assembly (DSA)

DSA combines self-assembly principles with top-down patterning to achieve large-scale patterning of nanoscale features. Block copolymers, consisting of two or more chemically distinct polymer blocks, spontaneously organize into periodic nanostructures when deposited onto patterned substrates. DSA enables the creation of dense, regular patterns with feature sizes below the resolution limit of conventional lithography, offering potential benefits for semiconductor device fabrication and data storage technologies.

4.Applications and Future Directions

The diverse approaches to nanotechnology pave the way for numerous applications across sectors.

4.1 Electronics and Photonics

Nanotechnology enables the miniaturization of electronic and photonic devices, leading to faster, more efficient technologies. Quantum dots, nanowires, and 2D materials hold promise for next-generation transistors, sensors, and displays.

4.2 Medicine and Healthcare

Nanomedicine offers targeted drug delivery, imaging, and diagnostics at the molecular level, revolutionizing healthcare. Nanoparticles, liposomes, and nanotubes enable precise control over drug release kinetics and tissue targeting, enhancing therapeutic efficacy and reducing side effects.

4.3 Energy and Environment

Nanotechnology plays a crucial role in renewable energy generation, storage, and efficiency improvement. Nanostructured materials enhance the performance of solar cells, batteries, and catalysts, while nanomembranes enable efficient water purification and desalination.

Conclusion

Approaches to nanotechnology encompass a diverse array of techniques, each with unique advantages and challenges. Bottom-up methods offer precise control over nanostructures but require careful design and synthesis, while top-down approaches enable scalability and compatibility with existing manufacturing processes. Hybrid approaches combine the strengths of both paradigms, unlocking new opportunities for complex nanostructure fabrication. As nanotechnology continues to advance, interdisciplinary collaboration and innovation will drive the development of transformative technologies with profound societal impact.